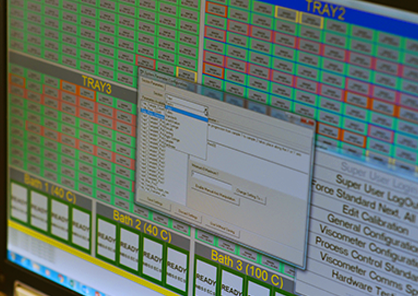

Priority Sample Processing

The sample batch file allows the user to set a priority flag within the batch to allow a sample to be processed out of sequence. It is not possible to edit samples that have already been processed or edit the sample that is in process at the time of editing.