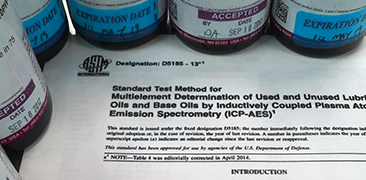

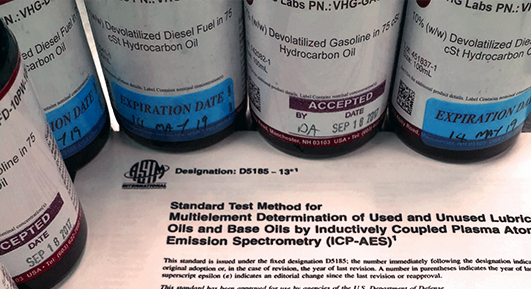

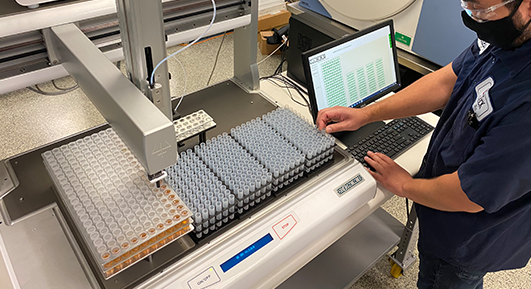

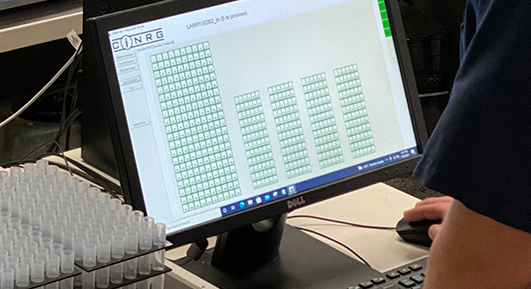

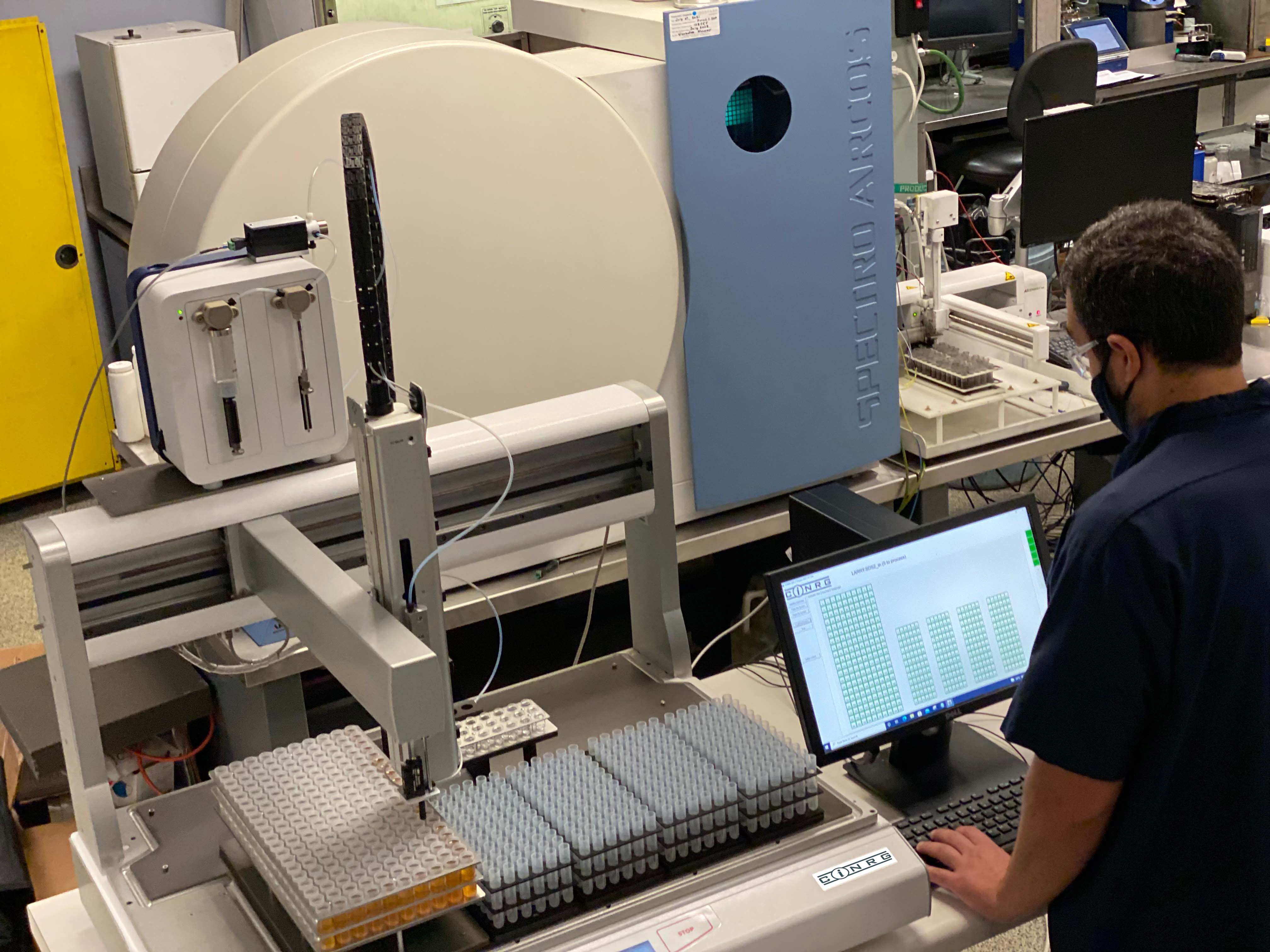

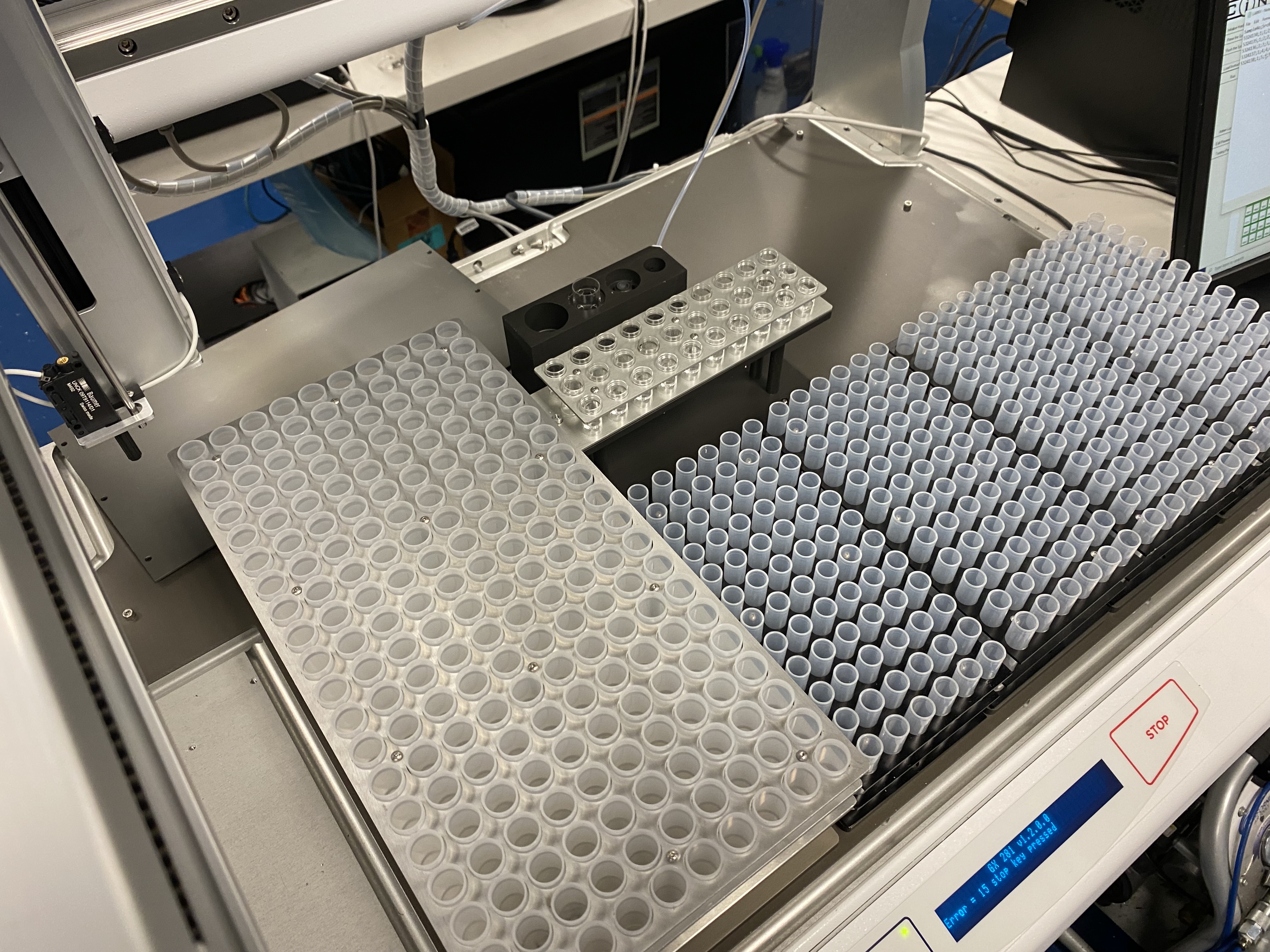

Made for ASTM D5185

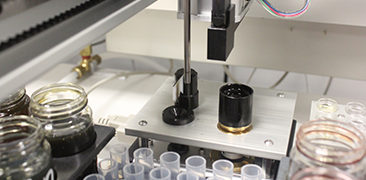

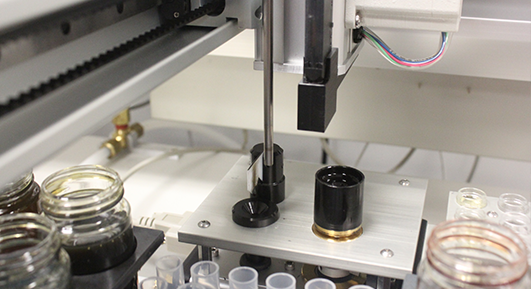

The system was designed for commercial laboratories that produce spectroscopic elemental results using the method ASTM D5185** and allows you to easily modify dilution ratios.