Particle counting is an essential part of oil condition monitoring and machinery health analysis. For in-house laboratories currently relying on portable particle counters such as the Beckman PODS, Hiac Royco 8000a, MP Filtra LPA, or the Diagnetics DCA, upgrading to an advanced solution can significantly improve the accuracy, reliability, and versatility of your testing. Enter the CINRG CS-APC-22M, an automated particle counter that is transforming the way labs handle contamination analysis in lubricants, hydraulic fluids, and other samples.

When we started the company, CINRG was dedicated to producing instrumentation solely for the oil analysis industry. Our ambition was to make instrumentation that could be put directly into production in an OA lab, that had low solvent usage, low sample volume requirement, low consumable costs and low cost of ownership. All coupled with high levels of automation. We've succeeded in this area, and when we developed the small format CS-APC-22M to complement our large format CS-APC-3 particle counter, our goal was to produce a lower cost instrument with the same capabilities of it's big brother for use in commercial satellite labs. We didn't expect to penetrate the on-site laboratory market, but were pleasantly surprised when we did. As a number of on-site particle counting instrument OEMs exit the market, a number of laboratories have been caught with no on-going support for their particle counting instruments. CINRG is happy that the CS-APC-22M is there to fill the gap.

A Step Ahead in Precision: ASTM D7647 Compliance

One of the standout features of the CS-APC-22M is its compliance with ASTM D7647, a methodology designed to address challenges that traditional particle counters often face. Labs working with fluids containing water, soft particles (like varnish precursors or certain oil additives such as foam inhibitors and friction modifiers) have long struggled with accurate particle counts. The CS-APC-22M overcomes these challenges by masking interferences that can skew results (for more information see my blog on Ghost Particles).

Traditional particle counters often overestimate particle counts in such complex fluids, leading to unnecessary alarms or maintenance interventions. The CS-APC-22M uses the method ASTM D7647 wherein samples are diluted with a masking solvent prior to particle counting. The CS-APC-22M instrument automatically performs the sample dilution so you can trust the data you’re collecting, ensuring you're only responding to legitimate contamination issues.

Why In-House Labs Should Make the Switch

For labs already equipped with portable systems like the Beckman PODS or Hiac Royco models, switching to the CS-APC-22M offers numerous advantages:

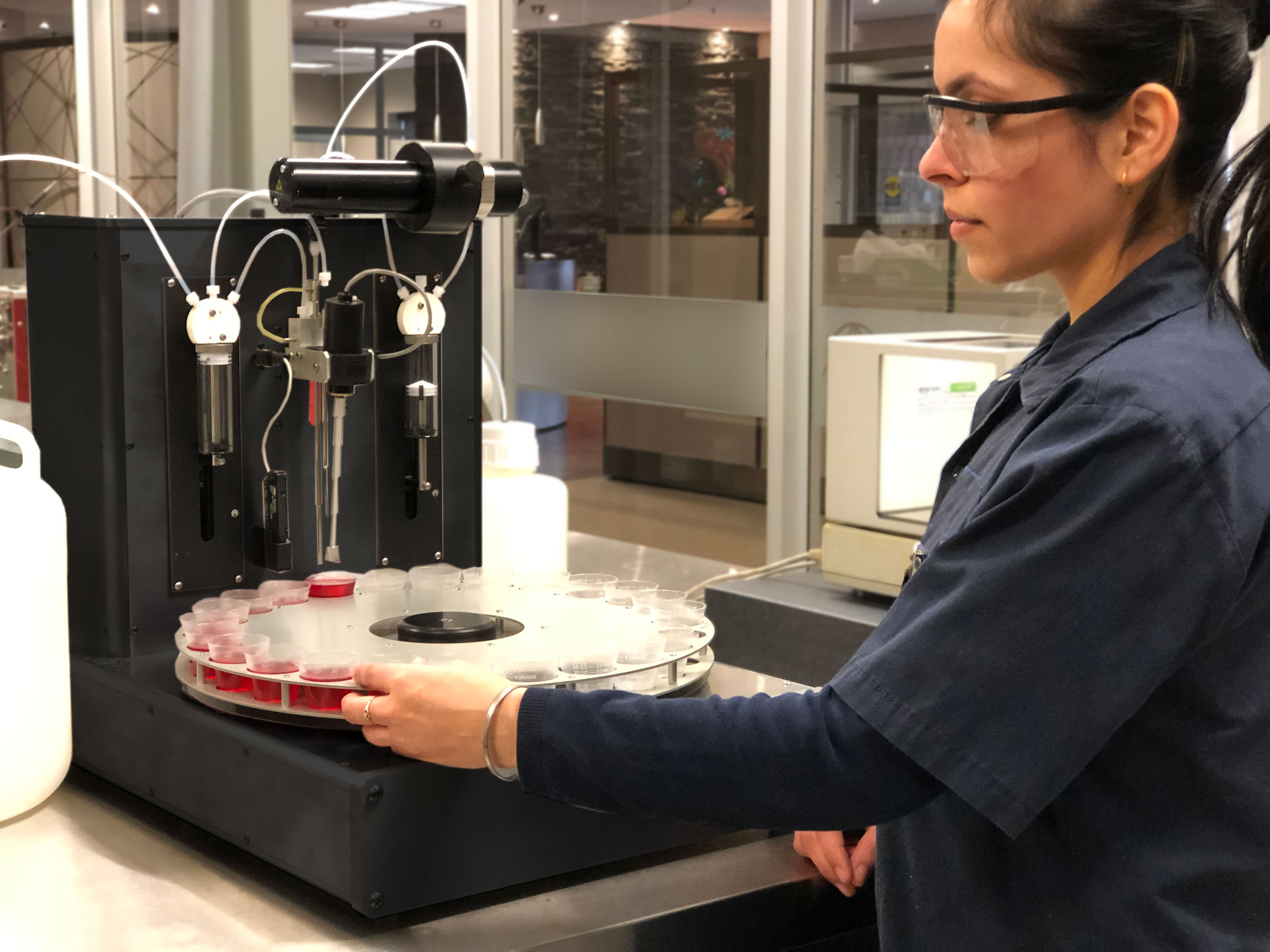

- Automation for Efficiency The CS-APC-22M eliminates the manual handling required in many portable systems, reducing operator intervention and the risk of human error. Its automated features streamline workflows, allowing your team to focus on analysis rather than troubleshooting inconsistent readings.

- Accuracy Across Challenging Fluids Whether you're analyzing samples with water content, varnish precursors, or certain additives, the CS-APC-22M ensures precise particle counts by accounting for these complexities. This capability reduces false positives and provides a clearer picture of your fluid’s condition. The instrument can provide particle counting on oils, water/glycol FRFs, fuels, transformer fluids, PE aviation hydraulic fluids, and many other samples that oil analysis laboratories are required to test.

- Enhanced Reporting and Integration Unlike older portable models, the CS-APC-22M integrates seamlessly with modern laboratory information management systems (LIMS) and provides enhanced data reporting. This functionality improves record-keeping and enables faster decision-making.

- On-site Calibration CINRG APCs are the only laser particle counters that can be calibrated on-site by your own technicians. CINRG provides a low cost calibration hardware kit, and CINStan calibration fluids, including the CS-CINSTAN-CFK calibration fluid kit, a calibration SOP and automated Excel spreadsheet to allow your technicians to perform your yearly particle counter calibration on-site, with your own staff. This provides for both a higher level of autonomy, and a lower total cost of ownership for your APC.

- Calibration Fluids CINRG is a manufacturer of calibration, verification and process control fluids, so you don't ever have to worry about not having the fluids necessary to calibrate and validate your paricle counting instrument (see our CINSTAN line of products).

- Future-Proof Design As regulations and testing methodologies evolve, having a system built to align with ASTM standards ensures your lab remains ahead of the curve. The CS-APC-22M represents a forward-looking investment in laboratory technology.

For in-house laboratories looking to upgrade their particle counting capabilities, the CINRG CS-APC-22M is a game-changer. By addressing the common pitfalls of traditional systems—particularly in samples containing water, insoluble material, and anti-foaming additives—it provides unparalleled accuracy and reliability. Its automation and adherence to ASTM D7647 further establish it as a best-in-class choice for labs aiming to optimize operations and ensure actionable insights.

If your lab is ready to move beyond portable systems like the Beckman PODS or Hiac Royco 8000a, it’s time to explore the CS-APC-22M. With this powerful tool in your arsenal, you’ll elevate your fluid analysis to a whole new level of precision and confidence.